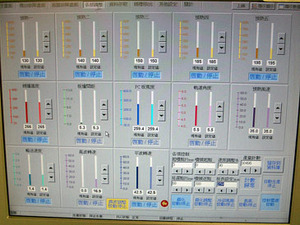

The wave solder inside the machine and the computer controlling the process listing the temperatures and other functions.

Foxconn provides many of the extra plastic components and connectors that are used on motherboards so there were plenty of boxes with its name on dotted around. The boxes contained every connector type you've ever seen on a Gigabyte board; some were neatly stacked, others were just littered in tubs like these Fujitsu solid aluminium capped capacitors.

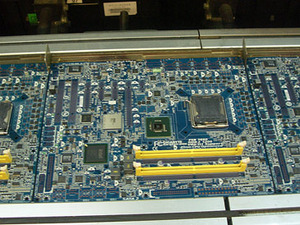

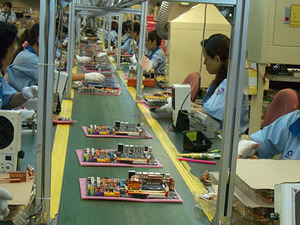

Next the PCB is transferred to the manual insertion line where all the plastic components, larger capacitors, chokes and CPU socket gets pressed on. Above a new Gigabyte GA-P45-DQ6 PCB gets its larger parts installed in place.

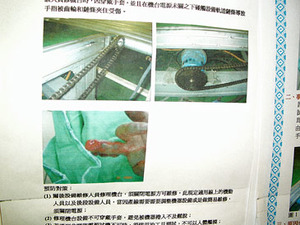

The last picture was a photo of just one of the few accidents that have been recorded on a section of wall, and yes, I picked one of the most gruesome! Basically, stick your finger in the gear and chain and it gets mangled, but not content with just a story Gigabyte takes a picture as well (and then I take a picture and put it on the Internet).

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.