What's the best water-cooling coolant?

In our previous roundup of six of the latest UV coolants, we found that they all performed very similarly with a modern pump, with no significant variations in flow rate or temperatures. As most are water-based or have water-like consistency, this isn't surprising, and means that looks are far more important if you're after colour or UV reactivity.

It's also worth remembering, then, that your purchase of coolant should be on looks and value alone - with all coolants we've tested so far performing nearly identically, and none offering long term protection against leak damage (all coolants we've tested will eventually become conductive, even if its slightly so), only cost and eye candy are of real concern.

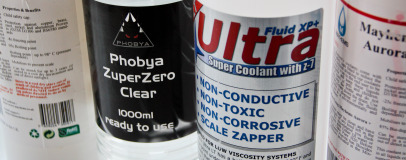

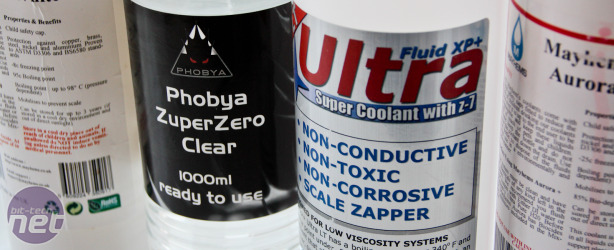

This time, we're looking at some of the non-UV coolants on the market, and also two of the latest pigment and pearlescent-effect coolants from Mayhem's, to see if all those pretty additives have a negative impact on performance. We've included the data we obtained in our last test to see which coolants are best overall too.

Click to enlarge

Testing methods

As you’d be a little crazy to water-cool your PC if it isn’t overclocked, we’ve used an Intel Core i5-2500K, which has been overclocked to 4.7GHz using vcore of 1.4V. The system was run with deionised water for a week to allow the thermal paste to cure.

We record the ambient room temperature to present the result as a delta T (the difference between the temperature of the CPU and the ambient temperature), to deal with any slight variations in the temperature in our testing environment. To measure flow rate, we used a Cole Palmer 120-1200LPH Flow Meter, reading results in litres per minute to obtain a more accurate reading given the meter is analogue. We filled the loop with deionised water to start with, then drained it, emptying each component, and filled the loop with the first coolant.

We then flushed each coolant out with deionised water, draining this as best we could between fills to ensure that there was no residual coolant left and only a minimal amount of deionised water – this is the best compromise between either leaving the loop drying for days on end or having six individual loops, which is clearly very impractical. We allowed each coolant to rid itself of air bubbles until non were visible in the coolant, tubes or audibly in the pump or blocks.

While long term testing to identify weaknesses in the coolants when used over longer periods with heat loads is preferable, this wasn't possible in the short time scale we had for testing. To do this properly, you'd need at least six months of testing per coolant with a heat source and this just wasn't possible, not to mention many of the coolants likely going end of life before we published the results. As such, our testing is done with off-the-shelf retail products so you can see exactly how your coolant will look and perform when it arrives.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.