Introduction

For most of you who know me and my particular modding tastes, I'm about to say something that's painfully obvious:I love acrylic.

There, I said it. My name is Brett Thomas, and I'm an acrylic addict. I can't get enough of the stuff. It can be opaque or transparent, coloured or clear, thick or thin. It can be bent, it can be cut, and it can be fused together like there was no joint at all. It can be sanded to translucency or flame polished until it's crystal clear. Acrylic and I have had a love affair since 2001, and I'm about to let you in on how you can join in.

Why? Because acrylic is one of the most undervalued materials in the world of modding. "But I see it everywhere," you say, "How can it be undervalued?"

Well, I think it is – despite its ubiquitous presence in modding (from windows to reservoirs to block tops to whole cases), very few people actually bother to understand it as a material. Aluminium and steel information is abundant – cutting guides, fastening, brake bending, laser cutting. Maybe because it's a more even material, maybe because it seems like it needs specialised tools.

Acrylic avoids much of that, but unfortunately it also avoids the wealth of information. Extruded or cell cast? Cut with what? How do you get rid of scuffs and scratches? When and why does it crack, and how can that be prevented?

These questions (and more) will hopefully be answered in the following pages – it's time to give acrylic its proper fifteen minutes of fame.

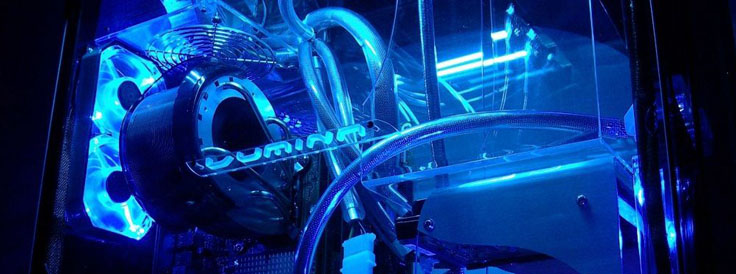

Lumina is one of the most popular mods of late, and it is made entirely from acrylic.

Understanding the material

Before we can get into why acrylic does what it does, we have to understand what acrylic is. Acrylic is also known as PMMA, short for poly(methyl)-methacrylate, which is a plastic derived from refined petroleum and oxygen. It is not the same as polycarbonate, which is considerably harder to work with and is (at least for modders) an inferior product.As a material, acrylic is often compared to glass for obvious reasons. It's about half the density of glass (and it is therefore much lighter), and translates about 98 percent of all visible light through it. It does not pass wavelengths smaller than 300nm through, so harmful UV rays are blocked from the start – but it can be treated to further prevent waves between 300-400nm (near UV). It is reflective from all surfaces (by about four percent naturally) due to its refractive index, so some prismatic effect is possible. This reflective property (much like the transparency property) can be adjusted by roughening the surface.

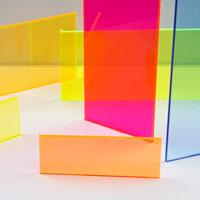

Acrylic comes in a wide

variety of colours and opacities.

Acrylic is made (for general consumption) in two ways:

- Extruded, where it is polymerised, melted (at about 250 degrees Celsius), poured through a die and air cooled; or,

- Cell cast, where it is polymerised and moulded at the same time in the mould.

On the other hand, cell cast requires moulds for each piece being made. These moulds have to withstand the chemical properties of forming the polymer, and the finished acrylic must stay in them until cool. This means many moulds and a slower final product, making cell cast considerably more expensive. However, because the "lattice" of polymers happens naturally in its final shape, cell cast is considerably more durable, scratch resistant and splinter/shatter proof.

In all, it is worth every penny to go for the cell cast if you intend to cut or shape it in any serious way. If all you need is a flat piece, extruded might do the trick in a pinch – but don't say I didn't warn you!

Why use it?

Knowing what acrylic is makes it easy to see why we would use it as a perfect case building and modding material. It's softer than metals, so it's easier to work with. It's harder to break than glass and it won't shatter if it does, so you have little damage taking it place to place. And it's lighter than glass while being still transparent, which makes a lot of difference.Better yet, because of its nature it can be milled, cut and machined easily with common wood tools, unlike glass or metal. And the veritable rainbow of colours, translucencies and reflectiveness make it easy to add to any mod. There are even pearlescent materials! Only glass can rival (or exceed) its colour spectrum – and glass is a very difficult animal to work with. I'll be covering that in a guide later this spring.

Acquiring the acrylic

So we know what acrylic is, how it's made and what type we need. Now, where do we buy it, and how do we know what's what?! Well, that's not an easy question – though there are some ground rules.First of all, we have to be able to tell acrylic from polycarbonate. Acrylic is sold under the following brand names: Plexiglas, Lucite, and [/i]Perspex[/i] are all common brand names for acrylic. There are more obvious ones as well – Acrylex and Acrylite, for example.

Where to buy your acrylic is a much more difficult task. Unfortunately, I'm not well aware of the options that you guys in the UK have, but I've heard some good things about ThePlasticShop, which carries quite a good selection. For those of us in the States, a couple good places to try are Delvies Plastics and McMaster-Carr. I've had good experience with both.

Wherever you are, you can also take a look at US Plastics or TAP Plastics, which ship internationally quite easily. Several modders have had good experience with them.

What is highly important is to avoid your local hardware shops, unless both they and you know exactly what you're getting. Anybody who reads my work normally will know this is very out of character for me to say – but you should at least avoid big chains. Speciality or hobby stores are still a good bet, as they'll be able to catalogue order and thus assure you're getting properly cell cast acrylic. Much of what you find in your local mega-store is extruded – so it's best to avoid that.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.