NBnO

by Nismo299Worklog

What happens when you give a crazy Swedish kid a case made for Robot AI control? We don't know either, but we're about to find out.

One relative newcomer to the forum, Nismo299, is just that kid – and his thoughtful Dad brought him home a tiny little case that's been designed for AI control over industrial robots. It’s not exactly made for a large amount of space, and to say it's lacking a bit of flare would be a dramatic understatement.

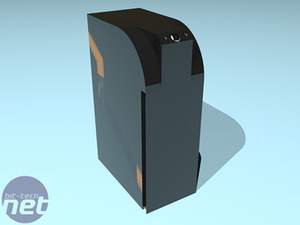

Of course, that's what the beauty of modding is – and Nismo decided that he'd use this opportunity to start off his very first full project. That's not to say he's never modded before, but those many little projects consisted of a couple days of tinkering as opposed to an out-and-out full project. So, we are honoured to present his first true endeavour – NBnO, or "Nismo's Black and Orange".

Unlike some lucky modders, Nismo isn't exactly blessed with a wealth of tools – instead, this case is being done with pretty much a hack saw and whatever old junk might happen to be in the garage. Not even a trusty Dremel was on hand for this "little" project.

The victim in Nismo's first modding project is certainly an unusual specimen – it's a tiny AI case used for industrial robots. Normally, it's built to hold little more than a couple fans, an ATX motherboard, a small PSU and a single hard drive. And what you see is exactly what he got – this thing isn't even stripped down.

The first thing on the list was to give the case a paintjob – after all, it can't be black and orange with no orange, right? So, Nismo went to work with a can of spray paint, a trigger attachment, and some masking tape in a makeshift paint booth.

Once the paint was done, it was time to start building the main shape of the case, which meant angle irons, pop rivets, some aluminium sheeting and a hacksaw. As brutal as it sounds, I'd say Nismo pulled it off quite elegantly – it's well worth a read in his log to see how he did all of this with a very small assortment of hand tools.

The front fascia of NBnO was to be very smooth, which meant that if the fans were staying to provide some actual cooling, the solid metal front would need to be offset to allow for airflow. Some spacers and machine bolts did the job perfectly, however, making the front flush with the beginning of the curved upper section.

Speaking of that upper section, it was time to begin working on that. But how do you bend aluminium with no real tools? The old school way – with a bucket, hammer, vice and pipe. Each of these was used to bend the strips and angle the curves that you see on the project.

With the top panel fairly tested by a painter-tape dry fitting, it was time to break out the riveter again. First, the switch box was assembled – then, the grille across the top was mounted. Finally, the whole assembly got a coat of epoxy to help smooth it down and fill in some of the grill holes. A lot of sanding later, and it is almost ready to mount – almost.

We can't wait to see what it looks like when it's mounted, or what Nismo is planning to do next. Judging by his track record, we won't have to wait very long before it shows up in his worklog. And if you're ever interested in how to do some great metalwork on an incredibly limited budget and tool set, that's exactly where you should be heading now.

Of course, on your way, perhaps you should show this homebuilt masterpiece a little love by taking a trip over to vote for NBnO by nismo299 as bit-tech's Mod of the Month for March of 2008!

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.