FiveWood by cc3d

Wooden cases.Just saying the word will immediately bring images to mind for our regular readers. Here, I'll save you the trouble of looking too far: Sangaku, Yuugou, Nakamura. If one of those wasn't the first one on your mind, make sure to let me know in the forums - I bet there won't be many more of that quality!

Nick's craftsmanship with his Japanese chisels and furniture creation is amazing, no doubt - but many people have been wondering, isn't there anything else?

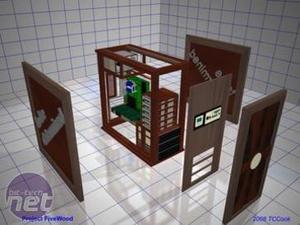

Today, we're going to let Chris Cook (aka cc3d) answer that question for you with a resounding 'Yes!" He's sprung back from his last project (Phase III) and left the spray paint, acrylic and metal behind. This time, he's gone to a more natural look - wood. Or, more specifically, five woods.

I know you're anxious to get into the mod, so I'll hand it off to Chris for a minute with a brief introduction before we get into his project. But before I do, I want to strongly urge you to take a trip over to his worklog for the project. There's a lot to see there that wasn't able to fit here!

Introduction

by Chris Cook, aka cc3dMy Grandfather, August Cook, and his wife Irma were amazing artists. August was a fantastic craftsman as well.- his works included oil paintings, wood carvings, sculpture and furniture craft. My other grandfather, T.J. Nuckols was a very creative woodcrafter as well. T.J. (or DD as he was called) always had creative ways to make things from wood.

It is this great gene pool of craftsmanship and creativity that I am abusing here.

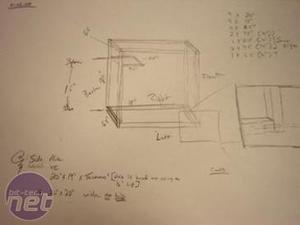

This project started on a napkin (well, a sheet of paper anyway). The concept images moved into the third dimension when I took my ideas to Lightwave 3D. This is where I excercise ideas while keeping the dimensions in mind.

While I wanted the entire project to be wood, I was going to be as pratical as possible in this regard. The motherboard tray was made from three different types of wood.

There have been a lot of questions regarding the thermal issues on this case (Nick, did you have these questions, too?). To answer some of the more common ones, I wanted to do a quick Q&A.

Q: Wood cases must be HOT, certainly no overclocker!

A: Why would a wood case be hotter than an aluminum case? Because wood is a better insulator than aluminum? It really does not matter as long as there is air flow. In fact, if the case is built of a better insulator and has proper airflow, it should be cooler because the airflow design is maintained without unexpected leaks or thermal transfer.

The FiveWood case uses a bottom to top airflow scheme. Vents in the bottom of the case allow cool air to flow up and into the case cavity while hot air is expelled through the three exhaust fans on top of the case. The case cover is about 1025 cm^2. The fans collectively open up a quarter of the top (~ 213cm^2). This is a big opening in the top of the case (where the heat rises to). These fans have a thermistor controlling their speed. More heat = faster fans and vice-versa.

Q: Are you concerned that this case will catch on fire?

A: If my airflow scheme is bad, I could reach temperatures of 45°C (113°F). Let's go nuts and say my case get's up to 90°C (194°F). The ignition point of most wood is around 350°C (662°F). As my case get's to that temperature, I would be more concerned about the cable insulation melting at around 176°C (350°F).

Q: Won't the wood dry out and crack and split apart?

A: Well, the wood was quite dry to begin with. Certainly dry enough build anything with (~6% - 8% MC). Wood computer cases are not the first electronic devices to be made of wood. They used to make these things called radios that were packed full of vacuum tubes. Vacuum tubes get a little warm.

Q: Wooden heat sinks on the 8800GTX cards?

A: These are 8800 GTX heat sink covers. The actual heat sinks are the original heat sinks. These covers do not affect temperature.

Trust me, I spent more than seven months on this rig. In that time, I promise that I took some time to consider the thermal effects. Not because it is wood, but because it is a computer case.

Speaking of time, I spent about 350 hours on this case, and that's probably an underestimate. Of those 350 hours, you might like to know that: 50 were spent on things that never made it into the case, 50 hours was spent just in getting the wood prepped, and too much time to track went into sanding the final boards. So very little ended up being spent on the shaping and assembly!

Of course, none of that includes the fifteen or so hours spent on planning, another 30 or 40 putting it into the project logs on my website and here on bit-tech, another 30 or 40 spent on trips to Home Depot, Lowes, etc., and a few hours here and there lusting after new technology (whether computer or woodworking).

Finally, I'd like to note one more thing - no pre-finished boards were used. By pre-finished, I mean that if it was sanded or even shaped into a nice piece we would normally call a board, I didn't touch it. Everything was bought raw, and then I cut to size, sanded and planed every piece you see. Also, there were no screws or nails used - boards were connected with joinery and a bit of glue.

With that said, I hope you enjoy this project. I know that I did!

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.