Qualcomm complains of TSMC 28nm capacity issues

April 19, 2012 | 13:24

Companies: #qualcomm #taiwan-semiconductor #tsmc

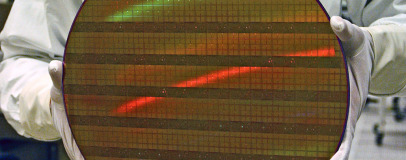

Taiwan Semiconductor's (TSMC) problems continue to mount, as one of its biggest customers on the 28nm process announces plans to look elsewhere for chip production.

TSMC admitted that it had run into capacity problems on its 28nm process node earlier this month, telling bit-tech that 'we are working very hard trying to solve the 28 nanometre capacity storage issue.' The company's admission came despite claims the month before that 'our 28nm production is normal, and all our 28nm customers are fully aware of our production status.'

Now TSMC has broken its silence on the matter, its customers are beginning to do the same with Qualcomm the first to indicate its displeasure with the semiconductor fabricator.

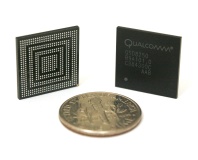

'We are seeing very strong demand for our industry-leading Snapdragon 4, MSM8960, and other 28nm products,' Qualcomm's chief executive Paul Jacobs told press and analysts during the company's earnings call late yesterday. 'Although the manufacturing yields are progressing per expectations, there is a shortage of 28nm capacity.

'We are working closely with our partners to bring additional capacity online, however the constraints on our 28nm supply are limiting our potential revenue upside this fiscal year,' Jacobs warned, before explaining that his company would be ploughing money into increasing supply of its 28nm chips. 'We're making the investments needed to improve the supply.'

A shift to other foundries - in addition to TSMC, rather than in place of - is likely to cost the company dearly. 'Demand for [28nm Snapdragon] chipsets exceeds supply. One of the things that you do when you look in to bring on additional sources, you tend to have more unplanned tape-outs,' Qualcomm president and chief operating officer Steven Mollenkopf explained. 'Essentially, you are taping out at a faster rate in order to move the ramp faster than you might have had to do it earlier. That is what we are doing today.'

Thus far, Qualcomm has not named the other foundries with which it is planning to work.

Meanwhile, TSMC itself has announced that it has dropped plans to offer customers two different processes at the 20nm node in favour of a one-size-fits-all solution. Speaking at the company's annual symposium, co-chief operating officer Shang-yi Chiang is reported by EE Times as stating that the differences between the two planned processes - believed to be high-power and low-power variants of the high-k metal gate (HKMG) process - were too small to justify offering both.

The move is a serious simplification for TSMC, which currently offers four different processes - high-performance, low-power, lower-power HKMG, and high-performance mobile-oriented - at the 28nm node. The company is expected to being offering 20nm production in 2013, followed by 14nm with the option of 3D field-effect transistors - FinFETs - in 2015. Chiang also told attendees that 18nm and 16nm process sizes had not been ruled out in the interim.

TSMC admitted that it had run into capacity problems on its 28nm process node earlier this month, telling bit-tech that 'we are working very hard trying to solve the 28 nanometre capacity storage issue.' The company's admission came despite claims the month before that 'our 28nm production is normal, and all our 28nm customers are fully aware of our production status.'

Now TSMC has broken its silence on the matter, its customers are beginning to do the same with Qualcomm the first to indicate its displeasure with the semiconductor fabricator.

'We are seeing very strong demand for our industry-leading Snapdragon 4, MSM8960, and other 28nm products,' Qualcomm's chief executive Paul Jacobs told press and analysts during the company's earnings call late yesterday. 'Although the manufacturing yields are progressing per expectations, there is a shortage of 28nm capacity.

'We are working closely with our partners to bring additional capacity online, however the constraints on our 28nm supply are limiting our potential revenue upside this fiscal year,' Jacobs warned, before explaining that his company would be ploughing money into increasing supply of its 28nm chips. 'We're making the investments needed to improve the supply.'

A shift to other foundries - in addition to TSMC, rather than in place of - is likely to cost the company dearly. 'Demand for [28nm Snapdragon] chipsets exceeds supply. One of the things that you do when you look in to bring on additional sources, you tend to have more unplanned tape-outs,' Qualcomm president and chief operating officer Steven Mollenkopf explained. 'Essentially, you are taping out at a faster rate in order to move the ramp faster than you might have had to do it earlier. That is what we are doing today.'

Thus far, Qualcomm has not named the other foundries with which it is planning to work.

Meanwhile, TSMC itself has announced that it has dropped plans to offer customers two different processes at the 20nm node in favour of a one-size-fits-all solution. Speaking at the company's annual symposium, co-chief operating officer Shang-yi Chiang is reported by EE Times as stating that the differences between the two planned processes - believed to be high-power and low-power variants of the high-k metal gate (HKMG) process - were too small to justify offering both.

The move is a serious simplification for TSMC, which currently offers four different processes - high-performance, low-power, lower-power HKMG, and high-performance mobile-oriented - at the 28nm node. The company is expected to being offering 20nm production in 2013, followed by 14nm with the option of 3D field-effect transistors - FinFETs - in 2015. Chiang also told attendees that 18nm and 16nm process sizes had not been ruled out in the interim.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.