How TIM works

I know what you're thinking - a whole article devoted to thermal paste? But wait - TIM can be fun (yes, I can - Ed.)!Okay, that might be an exaggeration but, with a system as complex as the PC, even the meanest part has vital significance. Without TIM, your new quad-core gaming machine probably wouldn't last long enough to load your favourite game.

A desktop CPU gives off a ridiculous amount of heat - up to 130W - in a small and very concentrated area, which is why we use a cooler to dissipate heat inside the case. The problem is that the cooler removes that heat via conduction.

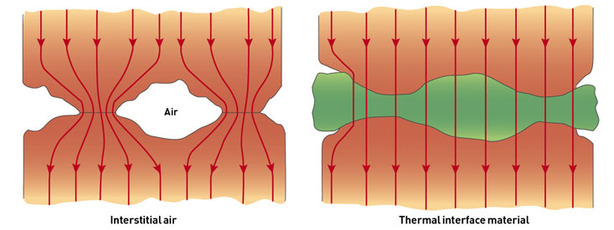

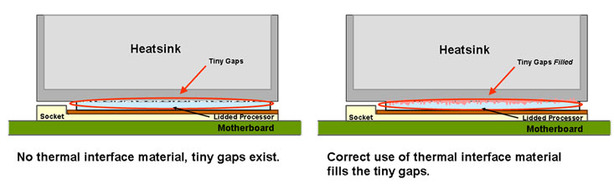

Easy, you might think; stick the smooth surface of the CPU against the smooth base of the heatsink, and you're away. However, even though both surfaces appear smooth, a microscope would reveal a hideous terrain of pits, grooves and undulations.

Where these abrasions occur, the two surfaces aren't making full contact with one another and therefore leave a pocket of air between them. As air is a poor conductor of heat, the effective contact area is reduced and these pockets of air are enough to prevent your cooler from working efficiently. TIM fills these tiny gaps to improve heat transfer.

This heroic paste fills the air pockets between the two surfaces, forming a continuous layer to conduct heat away from the CPU to the heatsink. As you'd imagine, this is why it's called thermal interface material.

TIM properties

Not any old grease or goo will do the job though. When producing TIM, manufacturers need to consider the following factors:- Thermal conductivity is the most important property of any thermal interface material - it's how well the material is able to transfer heat. This is usually measured in watts per metre kelvin (W/mK), whereby a higher figure means more thermal conductivity. The higher the thermal conductivity, the more effective the TIM will be when it comes to impacting your CPU temperatures. A material with poor thermal conductivity will be less efficient at transferring heat from the source and because of that, you'll need to invest more into your CPU cooler in order to achieve the same performance as you would with a better thermal interface material.

- Electrical conductivity is the material's ability to transfer electricity. As TIM operates in an area where vulnerable circuits may be nearby, high electrical conductivity isn't desirable. Most thermal interface materials are not electrically conductive these days as they are ceramic based, but some metal based compounds are still electrically conductive - they're not recommended for obvious reasons.

- The spreading characteristics of a compound determine its ability, given heat and pressure, to spread out and fill all the tiny air gaps between processor and heatsink. The manufacturer also needs to work out how thinly the material spreads. Generally, the thinner the layer of TIM, the more effective the heat transfer will be.

- A material's long-term stability and reliability is its ability to provide sufficient thermal conductivity over an extended period of time. Will the TIM creep, leaving vital areas uncovered? Will it become too runny and be pumped out of place by heat and pressure? Will it harden and crumble over time? These are things that can happen if you use a low-quality thermal interface material and can lead to overheating, but shouldn't be anything to worry about with higher quality compounds.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.