Researchers develop low-cost graphene ink

October 19, 2015 | 15:11

Companies: #university-of-cambridge

Researchers at the University of Cambridge have unveiled new inks based on wonder-material graphene which allow for low-cost, high-speed printing of electronic circuits.

Graphene is, at its heart, very simple. A carbon allotrope one atom thick, it can be produced in large quantities using little more than graphite sheets and sticky-tape yet its interesting properties have promised to revolutionise everything from semiconductors to batteries. Now, researchers have added a new use to the growing list: printing electronic circuits.

'We are pleased to be the first to bring graphene inks close to real-world manufacturing. There are lots of companies that have produced graphene inks, but none of them has done it on a scale close to this,' crowed Dr. Tawfique Hasan, of the Cambridge Graphene Centre (CGC), creator of the new production method. 'Being able to produce conductive inks that could effortlessly be used for printing at a commercial scale at a very high speed will open up all kinds of different applications for graphene and other similar materials.'

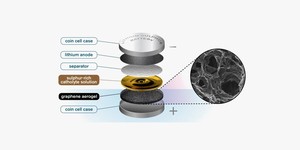

Hasan's method, developed at the University of Cambridge's Nanoscience Centre in partnership with local firm Novalia, sees graphene particles suspended in a special solvent mixture. This mixture is then added to traditional conductive water-based inks, and the ratio adjusted to reduce resistance considerably - and the graphene can be replaced with other materials, such as insulators, to create multi-layered circuits.

The resulting ink is far less resistive than carbon-based conductive inks, while also being significantly cheaper than silver-based inks - some 25 times less, Hasan claims, and capable of being run through a commercial printer at up to 100 metres per minute, meaning it scales up to industrial use well. 'This method will allow us to put electronic systems into entirely unexpected shapes,' claimed Novalia's Chris Jones of the new method. 'It’s an incredibly flexible enabling technology.'

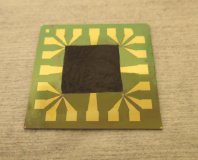

The team have announced plans to use the ink to produce low-cost, disposable bio-sensor devices based on radio frequency identification (RFID) and energy-harvesting designs, but have not announced a date for commercialisation.

Graphene is, at its heart, very simple. A carbon allotrope one atom thick, it can be produced in large quantities using little more than graphite sheets and sticky-tape yet its interesting properties have promised to revolutionise everything from semiconductors to batteries. Now, researchers have added a new use to the growing list: printing electronic circuits.

'We are pleased to be the first to bring graphene inks close to real-world manufacturing. There are lots of companies that have produced graphene inks, but none of them has done it on a scale close to this,' crowed Dr. Tawfique Hasan, of the Cambridge Graphene Centre (CGC), creator of the new production method. 'Being able to produce conductive inks that could effortlessly be used for printing at a commercial scale at a very high speed will open up all kinds of different applications for graphene and other similar materials.'

Hasan's method, developed at the University of Cambridge's Nanoscience Centre in partnership with local firm Novalia, sees graphene particles suspended in a special solvent mixture. This mixture is then added to traditional conductive water-based inks, and the ratio adjusted to reduce resistance considerably - and the graphene can be replaced with other materials, such as insulators, to create multi-layered circuits.

The resulting ink is far less resistive than carbon-based conductive inks, while also being significantly cheaper than silver-based inks - some 25 times less, Hasan claims, and capable of being run through a commercial printer at up to 100 metres per minute, meaning it scales up to industrial use well. 'This method will allow us to put electronic systems into entirely unexpected shapes,' claimed Novalia's Chris Jones of the new method. 'It’s an incredibly flexible enabling technology.'

The team have announced plans to use the ink to produce low-cost, disposable bio-sensor devices based on radio frequency identification (RFID) and energy-harvesting designs, but have not announced a date for commercialisation.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.