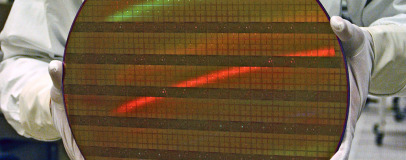

Intel has confirmed its intentions to migrate its fabrication plants to a 450mm wafer size, starting with its Oregon-based DX1 plant.

Speaking to Electronista, Intel's Mark Bohr, director of process architecture and integration, confirmed that the company was looking to move from the current 300mm wafer size to a more cost effective 450mm wafer size in the near future.

The company will start with the DX1 22nm plant in Oregon, which will be constructed to support both 300mm and 450mm wafer sizes side-by-side as the company prepares the plant to open in 2013.

Increasing wafer size could be a winning move for Intel: despite some complications that come as you increase the number of silicon chips you are creating on a single wafer, whether through a shrinking process size or an increase in wafer size, it holds the promise of reducing manufacturing costs and allowing Intel to turn out increasing quantities of chips even at lower yields.

It's likely that this latter factor is key in Intel's decision to make the move to 450mm: as the company invests in 22nm fabrication, there will be a period in which yields are down but demand is high - and by employing a larger wafer the company can attempt to compensate for that.

It's not yet known whether the research-centric DX1 plant will be the first to get 450mm support, or if Intel is planning on upgrading existing plants ahead of DX1's 2013 opening.

Are you pleased to see Intel working on techniques for producing processors more cost-effectively, or should the company be looking at cheaper ways of increasing yield rather than re-tooling all its fabs? Share your thoughts over in the forums.

Speaking to Electronista, Intel's Mark Bohr, director of process architecture and integration, confirmed that the company was looking to move from the current 300mm wafer size to a more cost effective 450mm wafer size in the near future.

The company will start with the DX1 22nm plant in Oregon, which will be constructed to support both 300mm and 450mm wafer sizes side-by-side as the company prepares the plant to open in 2013.

Increasing wafer size could be a winning move for Intel: despite some complications that come as you increase the number of silicon chips you are creating on a single wafer, whether through a shrinking process size or an increase in wafer size, it holds the promise of reducing manufacturing costs and allowing Intel to turn out increasing quantities of chips even at lower yields.

It's likely that this latter factor is key in Intel's decision to make the move to 450mm: as the company invests in 22nm fabrication, there will be a period in which yields are down but demand is high - and by employing a larger wafer the company can attempt to compensate for that.

It's not yet known whether the research-centric DX1 plant will be the first to get 450mm support, or if Intel is planning on upgrading existing plants ahead of DX1's 2013 opening.

Are you pleased to see Intel working on techniques for producing processors more cost-effectively, or should the company be looking at cheaper ways of increasing yield rather than re-tooling all its fabs? Share your thoughts over in the forums.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.