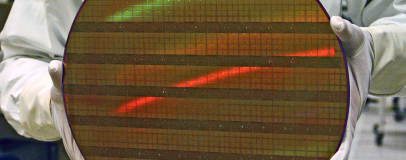

Intel is reportedly to spend $6 billion to upgrade its Fab 28 chip manufacturing facility in Kiryat Gat, Israel, to support manufacturing on a 10nm process node.

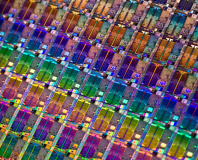

Intel's current state-of-the-art is using a 14nm feature size to produce its semiconductors, a shrinkage step that caused unexpected delays when it proved more challenging than first anticipated. 10nm is the next logical step in the company's slavish adherence to Moore's Law, a self-fulfilling prophecy by co-founder Gordon Moore that originally observed the number of transistors on a semiconductor roughly doubling in quantity every eighteen months. To keep cramming additional transistors into future processors without running into heat or footprint issues, those transistors have to keep getting smaller - hence the company's constantly-shrinking process node.

While not yet confirmed by Intel, newswire Reuters has received a statement from Israel's finance minister Yair Lapid that claims the company has settled on its facility in Kiryat Gat as getting the first 10nm support through $6 billion in investment and a $300 million government grant coupled with a ten-year reduction in corporate tax payments. 'Intel's investment is a strategic asset for Israel's industry,' Lapid claimed. 'This is the biggest investment by a foreign company ever in Israel and is further proof that Israel is at the forefront of technology and innovation.'

The massive investment comes less than a year after Intel mothballed its new Fab 42 facility in Arizona following the company's 14nm issues. At the time, Intel's Chuck Mulloy suggested that Fab 42 could be used for future process nodes - meaning 10nm - but with the Israel deal seemingly signed and sealed that seems unlikely to happen any time soon.

Intel's current state-of-the-art is using a 14nm feature size to produce its semiconductors, a shrinkage step that caused unexpected delays when it proved more challenging than first anticipated. 10nm is the next logical step in the company's slavish adherence to Moore's Law, a self-fulfilling prophecy by co-founder Gordon Moore that originally observed the number of transistors on a semiconductor roughly doubling in quantity every eighteen months. To keep cramming additional transistors into future processors without running into heat or footprint issues, those transistors have to keep getting smaller - hence the company's constantly-shrinking process node.

While not yet confirmed by Intel, newswire Reuters has received a statement from Israel's finance minister Yair Lapid that claims the company has settled on its facility in Kiryat Gat as getting the first 10nm support through $6 billion in investment and a $300 million government grant coupled with a ten-year reduction in corporate tax payments. 'Intel's investment is a strategic asset for Israel's industry,' Lapid claimed. 'This is the biggest investment by a foreign company ever in Israel and is further proof that Israel is at the forefront of technology and innovation.'

The massive investment comes less than a year after Intel mothballed its new Fab 42 facility in Arizona following the company's 14nm issues. At the time, Intel's Chuck Mulloy suggested that Fab 42 could be used for future process nodes - meaning 10nm - but with the Israel deal seemingly signed and sealed that seems unlikely to happen any time soon.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.