Die-hard Burn-in Technology Now On All GeIL DDR2 Product Series

November 6, 2008 | 22:35

Companies: #geil

Industrial Engineering on Every GeIL Memory

- DBT Enhanced DDR2 Series -

Following DDR2 So-Dimm Series, DDR2 Gaming Series, now GeIL DDR2 Value, Ultra and Mac Series will be the next product lines to undergo DBT process and complete the DBT migration of the entire GeIL DDR2 lines of product. DBT enhanced DDR2 memory will provide user of all levels superb stability, performance and reliability memory modules for their PC systems. No more system-hang or “blue-screen-of-death” due to unstable and weak memory! With DBT, GeIL is to prove we are tough on performance and tougher on reliability!

GeIL will be announcing the following product lines that are scheduled to adopt DBT in the near future.

- GeIL, Setting the Benchmark -

The DBT, with its advanced production technological edge will enable GeIL to produce a even wider range of memory products such as low power consumption memory, industrial (IPC & embedded system) memory or even memory with the most demanding military specification. Furthermore, DBT will improve the reliability of the entire GeIL product lines and achieve ultra low defective rate.

A new benchmark will be set for the DRAM industry with GeIL’s Die-hard Burn-in Technology

GeIL has once again raised the bar on memory production technology by implementing Die-hard Burn-in Technology into it's memory production.

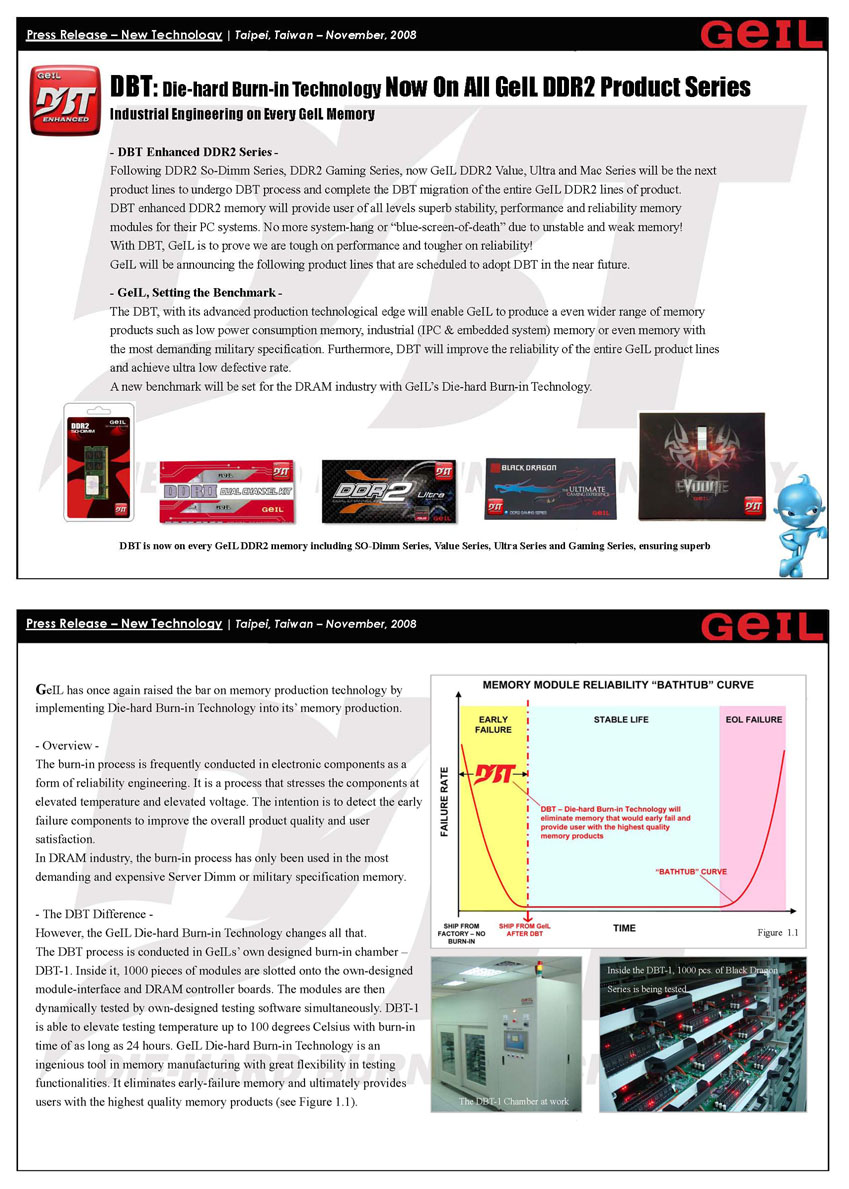

The burn-in process is frequently conducted in electronic components as a form of reliability engineering. It is a process that stresses the components at elevated temperature and elevated voltage. The intention is to detect the early failure components to improve the overall product quality and user satisfaction.

In DRAM industry, the burn-in process has only been used in the most demanding and expensive Server Dimm or military specification memory.

- The DBT Difference -

However, the GeIL Die-hard Burn-in Technology changes all that. The DBT process is conducted in GeILs’own designed burn-in chamber – DBT-1. Inside it, 1000 pieces of modules are slotted onto the own-designed module-interface and DRAM controller boards. The modules are then dynamically tested by own-designed testing software simultaneously. DBT-1 is able to elevate testing temperature up to 100 degrees Celsius with burn-in time of as long as 24 hours. GeIL Die-hard Burn-in Technology is an ingenious tool in memory manufacturing with great flexibility in testing functionalities. It eliminates early-failure memory and ultimately provides users with the highest quality memory products (see Figure 1.1)

- DBT Enhanced DDR2 Series -

Following DDR2 So-Dimm Series, DDR2 Gaming Series, now GeIL DDR2 Value, Ultra and Mac Series will be the next product lines to undergo DBT process and complete the DBT migration of the entire GeIL DDR2 lines of product. DBT enhanced DDR2 memory will provide user of all levels superb stability, performance and reliability memory modules for their PC systems. No more system-hang or “blue-screen-of-death” due to unstable and weak memory! With DBT, GeIL is to prove we are tough on performance and tougher on reliability!

GeIL will be announcing the following product lines that are scheduled to adopt DBT in the near future.

- GeIL, Setting the Benchmark -

The DBT, with its advanced production technological edge will enable GeIL to produce a even wider range of memory products such as low power consumption memory, industrial (IPC & embedded system) memory or even memory with the most demanding military specification. Furthermore, DBT will improve the reliability of the entire GeIL product lines and achieve ultra low defective rate.

A new benchmark will be set for the DRAM industry with GeIL’s Die-hard Burn-in Technology

GeIL has once again raised the bar on memory production technology by implementing Die-hard Burn-in Technology into it's memory production.

The burn-in process is frequently conducted in electronic components as a form of reliability engineering. It is a process that stresses the components at elevated temperature and elevated voltage. The intention is to detect the early failure components to improve the overall product quality and user satisfaction.

In DRAM industry, the burn-in process has only been used in the most demanding and expensive Server Dimm or military specification memory.

- The DBT Difference -

However, the GeIL Die-hard Burn-in Technology changes all that. The DBT process is conducted in GeILs’own designed burn-in chamber – DBT-1. Inside it, 1000 pieces of modules are slotted onto the own-designed module-interface and DRAM controller boards. The modules are then dynamically tested by own-designed testing software simultaneously. DBT-1 is able to elevate testing temperature up to 100 degrees Celsius with burn-in time of as long as 24 hours. GeIL Die-hard Burn-in Technology is an ingenious tool in memory manufacturing with great flexibility in testing functionalities. It eliminates early-failure memory and ultimately provides users with the highest quality memory products (see Figure 1.1)

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.