Introduction

Ah, the fabled Lian Li. It seems that there's a bit of a love-hate relationship with the brand in the modding community, with some people loving it and some people hating every last sharp edge.Whether you love it or hate it, there's no doubt that Lian Li is a name that is synonymous with a quality product. Who cares if you had to pay an arm and a leg? Your sister didn't need hers (you do, though...how else could you mod?), and that first-born you promised away was probably just going to be a spoiled brat anyhow.

Of course, that's assuming you had to buy the case in the first place - a problem which one of our regular modders, Ediejo, didn't really have to encounter. He was handed a rather nice Lian Li 201b at CeBIT 2006, encouraged to see what he could create after such great mods as the Stacker mod with his partner in crime and fellow avid bit-tech modder, Snakez.

Ediejo, never lacking for big ideas involving tremendous amounts of bling, was quick to accept the case on offer. He was also quick to accept a great deal on some carbon fibre sheets that he stumbled upon - could it be a match made in heaven?

Carbon fibre is not an easy material to work with, particularly when it's already been treated with resin - at that point, you'd better bring your demolition equipment. But, beggars can't be choosers - and though Ediejo had a lot of work ahead of him, he's never been one to pass on an opportunity to create a new, unique project.

So, with a little help from his friends over at Point of View and a lot of encouragement from fellow modders here on his bit-tech worklog, it was time to dig in and turn this bog-standard Lian Li 201b into something special - Carbon Li.

Getting our feet wet

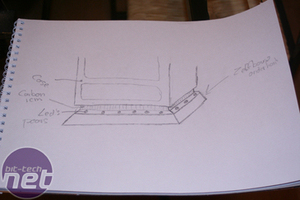

Ediejo started Carbon-Li from the ground up - literally. He had wanted to build some kind of 'base' back when he designed Extreme Lian Li, and thought this might be the perfect time to do that.Plan your mod! No, really - as you can see, Ediejo starts out with at least a rough idea of where he wants to go with Carbon-Li, an idea that turned into reality as he welded the base at work. If Ediejo's boss is reading this, he welded it...umm, at home. Yeah, that's it. Not at work.

The finished base was designed to be slightly smaller than the case at the attachment point, and flaring out at the case's edges. This creates a little recess which Ediejo had big plans for.

The first step to the base was to drill plenty of holes in it - twenty four, to be exact. That way, when submerged, it would sink quickly or even strain your spaghetti. Or, maybe it was to hold some LEDs...yeah, that's probably more likely.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.