Sand casting and panel fabrication

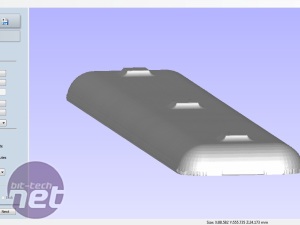

This was by far one of the most time consuming and challenging parts of the entire project. It began with creating a 3D toolpath to run on a CNC machine as I needed to make a set of aluminium castings which had curves that had to match perfectly. I had originally planned to used wax to create the castings:Click to enlarge

However it proved too slow to machine on my homemade CNC machine, and was too time consuming to sand and repair any imperfections, so I was forced to use wood to create the mould for the sand casting, using the toolpath I had already created:

Click to enlarge

Once the wooden moulds were finished I then took them to the sand casters. Unfortunately however I wasn’t able to take photos of my moulds being casted but there were some others which were surprisingly complex:

Click to enlarge

They use a mould to create a sand form using a special resin or oil to bind the sand, which molten aluminium is then poured into. Each mould must leave at least a 5mm gap for the aluminium to pour into, as it cools very quickly as it travels through the mould.

Click to enlarge

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.