Omega Desk by Daniel Fessler (Squigly)

Desks are certainly the projects of the moment, but while you'd think they're all pretty similar, every one we've seen has somehow looked very, very different to the last. L3p D3sk and The Next Level were both deserving Mod of the Year winners, but each deserved to win in their own right, thanks to unique skills being applied as well as new looks and new materials.

Just when we thought we'd seen all the possible variations on the theme, South Africa-based bit-tech forum member Squigly comes up with yet another intriguing take on the PC desk. The project nearly won Mod of the Month in July last year too.

It's over to Daniel, who has kindly taken the time to show us how he made it and if you want to see more, check out his project log here.

I have always been intrigued by desk builds, having components incorporated neatly with their own purposeful space, but I wanted something with a little more form than pure function.

I set off looking at different desk designs for some inspiration and of course this search inevitably led me to the 2011 MOTY winner, the l3p d3sk and that was it... I wanted, nay, NEEDED some of that awesomeness in my life.

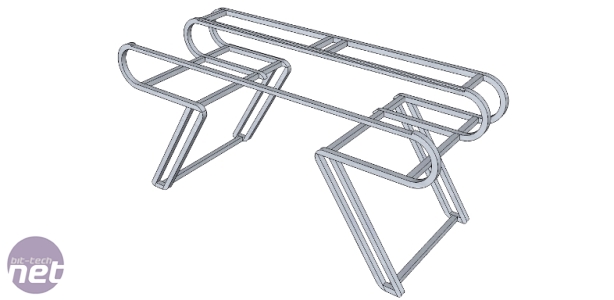

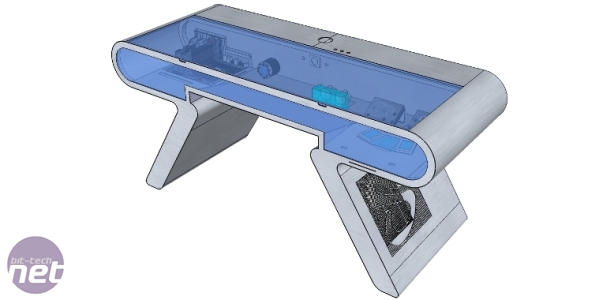

I spent a good few months with Google Sketchup and finally came up with a workable design for me to start with. The design would need to not only house the computer with ample space for cable management but also the required space for all the water cooling equipment this was the start of my journey.

Having never attempted a scratch build I had my doubts as to if I was biting off more than I could chew, but to all those thinking of embarking on a scratch build, don't doubt, plan.. measure.. plan some more and measure twice more.. then just get it done.. before you know if, you're looking at your vision.. a VERY satisfying moment!

I was able to find a supplier that could roll the tubing I needed for the frame components as that was one toolset I didn't have access to. Fortunately though I did have access to a workshop that had a host of fun tools, like milling machines, lathes, press brakes, plate rollers, welding equipment, pretty much everything I would need to get the build done.

After machining out areas for the DVD drive and glass I set about welding up the frame. I am no pro welder but the joins held fast and were cleaned off as to not interfere with the aluminium cladding.

Desks are certainly the projects of the moment, but while you'd think they're all pretty similar, every one we've seen has somehow looked very, very different to the last. L3p D3sk and The Next Level were both deserving Mod of the Year winners, but each deserved to win in their own right, thanks to unique skills being applied as well as new looks and new materials.

Just when we thought we'd seen all the possible variations on the theme, South Africa-based bit-tech forum member Squigly comes up with yet another intriguing take on the PC desk. The project nearly won Mod of the Month in July last year too.

It's over to Daniel, who has kindly taken the time to show us how he made it and if you want to see more, check out his project log here.

I have always been intrigued by desk builds, having components incorporated neatly with their own purposeful space, but I wanted something with a little more form than pure function.

I set off looking at different desk designs for some inspiration and of course this search inevitably led me to the 2011 MOTY winner, the l3p d3sk and that was it... I wanted, nay, NEEDED some of that awesomeness in my life.

Click to enlarge

I spent a good few months with Google Sketchup and finally came up with a workable design for me to start with. The design would need to not only house the computer with ample space for cable management but also the required space for all the water cooling equipment this was the start of my journey.

Click to enlarge

Having never attempted a scratch build I had my doubts as to if I was biting off more than I could chew, but to all those thinking of embarking on a scratch build, don't doubt, plan.. measure.. plan some more and measure twice more.. then just get it done.. before you know if, you're looking at your vision.. a VERY satisfying moment!

Click to enlarge

I was able to find a supplier that could roll the tubing I needed for the frame components as that was one toolset I didn't have access to. Fortunately though I did have access to a workshop that had a host of fun tools, like milling machines, lathes, press brakes, plate rollers, welding equipment, pretty much everything I would need to get the build done.

Click to enlarge

After machining out areas for the DVD drive and glass I set about welding up the frame. I am no pro welder but the joins held fast and were cleaned off as to not interfere with the aluminium cladding.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.