Applying the Foil

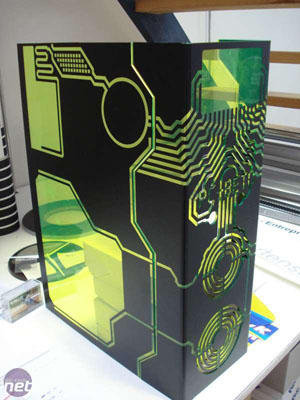

After the bending, all that was left was to see if the part fitted on the frame. Luckily it fitted like a glove, which let me continue to the hard part - applying the foil that was to be the key feature of the whole design.The foil was cut with a Roland foil cutter. I couldn't cut out the centre part, because it would be too hard to align to the ventilation cut-outs on the acrylic, so this had to be done by hand later. I also had to use soapy water to apply the foil to the centre piece, as it would have been impossible to control otherwise.

As mentioned earlier, the centre had to be cut out manually, so this was achieved with a scalpel knife, and then filed clean. This was quite a nerve-wrecking moment, as I was afraid the knife would slip, ruining the entire foil sheet. With an insane amount of patience, it all went according to plan.

The side panels received the same treatment, although they were a little easier since I could apply the foil without using soapy water, and there was no need to cut off any extras. The holder that enables the PSU to stand up vertically was also made, and received the foil treatment too.

I was stoked when I first assembled everything together, and I couldn't wait to share what I had made. The result was beyond my wildest imagination, and I knew that the mod had really taken off. Little did I know that the hardest parts were yet to come.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.