Side panel assembly

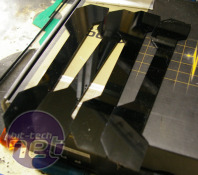

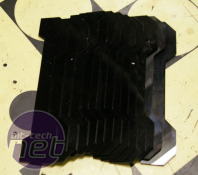

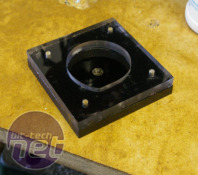

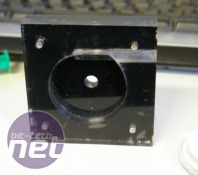

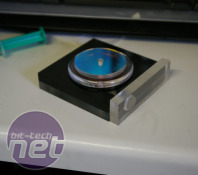

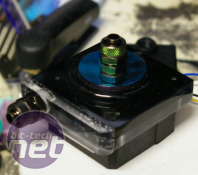

After cutting out all parts that were needed to build the side panels, we started to assemble them. We first had to clean them to avoid any problems with the glue, as the Perspex cement we use, called Acryfix, is really thin and not easy to handle without an injection needle.In the time that the glue needed to dry and harden, we started to build a custom Laing pump top for the water-cooling system. We also modified the CPU cooling block so that it fitted more easily inside our system.

The next step was to cut out the other sections, including the base, which we needed to build the bottom part of the case so that we could start to assemble it.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.