Precision was this point to the millimetre, and it would be even more important with these case covers since they were going to be used for making moulds. I love 3M tape.

The completion of the case covers now meant they had to get tac welded. A lot of praying went on here! I knew there would be warping from the heat and that would cause distortion and I wanted these covers to fit together pretty seamlessly. My fabrication skills on the precision level were put to the test.

After tac welding, I was able to finally move onto the mould-making phase. The covers needed to be additionally reinforced with bond-o and short hair glass filler bond-o then sanded smooth for the preparation of gel-coat.

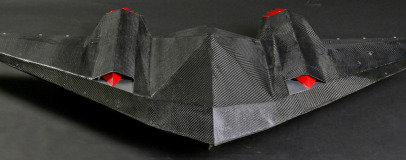

The reason moulds needed to be made was for the vacuum resin infusion process in moulding and curing carbon fibre. This process of infusion has never been tried before on a computer case. It was something completely new and along with carbon fibre on this scale really had never been done before. I like blazing a path, because I am inventor!

Click to enlarge

The completion of the case covers now meant they had to get tac welded. A lot of praying went on here! I knew there would be warping from the heat and that would cause distortion and I wanted these covers to fit together pretty seamlessly. My fabrication skills on the precision level were put to the test.

Click to enlarge

Click to enlarge

After tac welding, I was able to finally move onto the mould-making phase. The covers needed to be additionally reinforced with bond-o and short hair glass filler bond-o then sanded smooth for the preparation of gel-coat.

Click to enlarge

Click to enlarge

The reason moulds needed to be made was for the vacuum resin infusion process in moulding and curing carbon fibre. This process of infusion has never been tried before on a computer case. It was something completely new and along with carbon fibre on this scale really had never been done before. I like blazing a path, because I am inventor!

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.