What is Vacuum Resin Infusion? It is the process in which a vacuum is used in mould to transfer resin throughout the composite fabric creating a “perfect” resin weight to strength ratio part. I chose to infuse the lower cover first and it ended in failure due to poor flow design!

$500 straight into the trash and I felt a pressure on my body that I didn't think I could do this. I racked my head over my flow design again and again. The resin really needed to be directed under a vacuum. I added two more flow lines with infusion connectors. I would do an infusion from multi-entry resin points, thereby making sure the entire part got covered with resin.

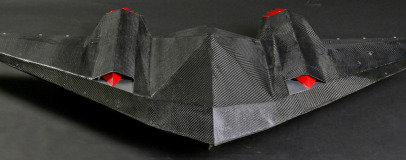

The layout process, then: wax, adhesive spray, lay in carbon fibre composite layers, seal tape, cut carbon fibre access, lay out nylon peel ply then cut, then flow media and cut, run flow line with infusion connectors, seal vacuum bagging material to seal tape, hook up tubing to vacuum pump, mix up resin and begin infusion. Lastly pray!

Click to enlarge

Click to enlarge

$500 straight into the trash and I felt a pressure on my body that I didn't think I could do this. I racked my head over my flow design again and again. The resin really needed to be directed under a vacuum. I added two more flow lines with infusion connectors. I would do an infusion from multi-entry resin points, thereby making sure the entire part got covered with resin.

Click to enlarge

Click to enlarge

The layout process, then: wax, adhesive spray, lay in carbon fibre composite layers, seal tape, cut carbon fibre access, lay out nylon peel ply then cut, then flow media and cut, run flow line with infusion connectors, seal vacuum bagging material to seal tape, hook up tubing to vacuum pump, mix up resin and begin infusion. Lastly pray!

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.