Water Cooling

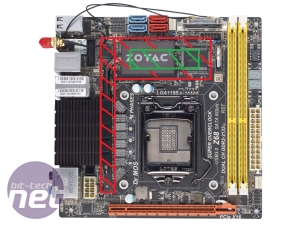

One of the main features of the project is water cooling. It's a useful tool for getting rid of heat in small places when installing numerous 120mm fans isn't an option. The only fan in the case, apart from the PSU, will be a 180mm SilverStone Air Penetrator fan in the roof. It's common for smaller projects to have a single exhaust fan because there simply isn't the room on other panels of the case. Here, the fan will be a major feature in the roof. However, with the rest of the case being nearly seamless, we had to add the large grilles at the front to allow air in.With the general air flow and radiator location decided, we set about deciding what else to water-cool. The CPU was obvious, as was the graphics card. The Zotac Z68 ITX WiFi motherboard, sadly, isn't amazingly popular and as such, there are no VRM or chipset waterblocks available for it. A universal chipset block may have fitted, but this would leave the VRMs exposed and in need of some form of cooling.

Click to enlarge

The original motherboard heatsink consisted of two separate heatsinks joined by a heatpipe. The VRM section in particular is extremely narrow, with a significant amount of other motherboard components surrounding it. The heatsinks got extremely hot, even in a larger case, so water-cooling them would be hugely beneficial and negate the need for an additional fan.

Click to enlarge

In the end we decided to attempt to make a custom waterblock. This would be comprised of a sheet of copper acting as the contact plate, with a standard VRM waterblock attached to it to add the motherboard to the water-cooling loop. The copper plate would be cut to size, avoiding no-go areas that could result in a lot of smoke and a dead motherboard, and would cover the VRMs (both of them), chipset and a Nuvoton NCT6776F sensor chip next to it that also gets a little warm.

Click to enlarge

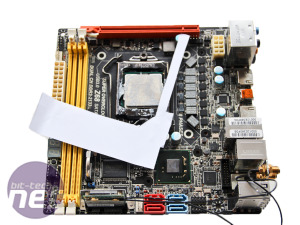

The first step in making your own motherboard block is to make a template which you can transfer to the copper sheet. We just used paper and, having removed the heatsinks, we began chopping it down to size, adding holes for various motherboard components to poke through to prevent short circuits. Our initial concerns were that at certain points, the copper plate would be fairly narrow, which would clearly impact on the amount of heat it could transfer from the VRMs up to the waterblock area. However, given the stock heatsink is passive with no help from and fans, we doubted our solution would be any worse.

We used 0.9mm copper sheet, which was surprisingly cheap. Aluminium would also work well, but before you start quoting facts about galvanic corrosion and calling us heretics for recommending the mixing of metals, the aluminium sheet wouldn't be in contact with the coolant, only the contact plate of the VRM waterblock.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.