Radiator

As the system includes two water-cooled power supplies, water-cooled CPU, chipset and video card, I needed a radiator that could handle cooling so many parts. I'm no water-cooling expert, so to me this meant at least a 240mm radiator, just to be safe. It also had to: fit inside the case, draw in cool outside air (not hot air off components), and it had to have a shroud over the intake, and between the fans and the radiator.The design meant the radiator had to fit across the end of the case to allow an air intake in the end (for the cool outside air), to enable the exhaust from the fans to blow across the motherboard components to aid cooling, and simply because there was no room to fit it any other way!

One slight problem: all the 240mm radiators I looked at would never fit across the end of the case - their corners stuck out too much (or I should say my case was too narrow). Two 120mm fans, side-by-side, fitted across the end of my case, but all the 240mm radiators I looked at were longer than the two 120mm fans together. The solution: a custom-built radiator!

Like I said, I'm no water cooling expert, so I turned to Willie at HWLabs for help. HWLabs make the excellent Black Ice series of radiators, which I had experience with, having used a chrome Black Ice Xtreme 120 in my Orac³ project. HWLabs were very keen to support the project and agreed to modify something for me based on my design.

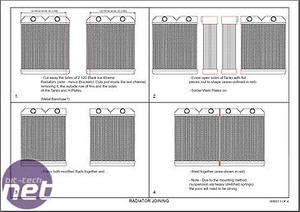

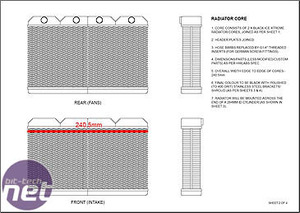

The result: two 120mm Black Ice Xtreme Pro radiators cut and welded together to create an ultra-compact 2x120 rad - exactly the width of the two 120mm fans on it. It fitted perfectly and, as it acts as two radiators, it gives me the option of running two independent loops or daisy-chaining them together via the centre inlets and running it as one big radiator. By pure coincidence, it also fitted neatly into the whole 'Noah's Ark' theme I suddenly found myself experiencing: two radiators, two pumps, two PSUs, two hard drives.

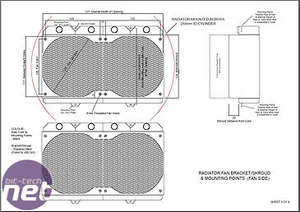

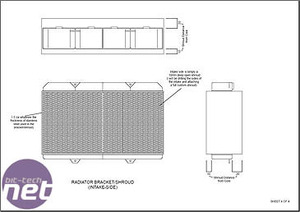

The fan shroud is built-in as part of the steel enclosure and gives about 25mm clearance between the fans and the radiator core.

The designs I submitted to HWLabs had to be pretty comprehensive - not only were the dimensions important, but I had a specific idea on how to join the two radiators together which I wanted to put across clearly. I drew all the plans up in Adobe Illustrator, after HWLabs had sent me PDF files with the technical drawings and measurements of a 120mm Black Ice Xtreme radiator to base things on.

I included a step-by-step diagram of how I thought the 120mm radiators should be cut and joined, and a diagram of the final core dimensions. There was a lot of email and MSN involved, especially with the shroud, as I wanted stainless steel and I think that was a first for HWLabs also; the stainless steel required different solders and was a lot harder to work with than the brass and copper normally used in radiators.

Needless to say, they came through like champions. It was great to work with a manufacturer who is so intimately involved with the enthusiast community. They knew exactly what I was after and how it was going to be used from the beginning.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.