PowerBookWorm

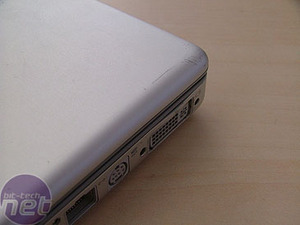

Regular readers will know that the majority of my day is spent attached to my beloved Apple PowerBook. A 1GHz G4 machine with 768MB of RAM and Radeon 9600 graphics, it's my daily workhorse, despite the prevalence of high-powered PC workstations round here. Why? Well, it's all about OSX, for me.My PowerBook goes with me absolutely everywhere. It's been around the world more times than I can count, to innumerable Starbucks coffee houses, to parks, gardens, exhibitions - everywhere I think I might be able to find 5 minutes to answer email.

However, those who know me will also know that I'm not the most careful of people. I can be clumsy and more than a little reckless on occasion. It was not an entirely unexpected event, then, when my PowerBook decided to give up the ghost.

The problem? The hard drive. Apple fitted a 60GB 4000RPM drive in the model I bought back in January 2004, and it simply had taken too much punishment. It was crashing randomly; would only boot 25% of the time and made working in PhotoShop an unbelievable chore. So, I managed to get it to limp along long enough to dump my data to DVD-R and then I decided I was going to pull it out and replace it.

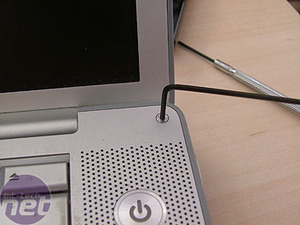

My warranty was gone, so there was no hope of a replacement from Apple. I grabbed a 80GB, 5400RPM Fujitsu drive and decided to go about ripping open my baby. I thought you might be interested to see me rip open a PowerBook and mod in a new hard drive, so here's the procedure.

Laptoposcopic surgery

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.