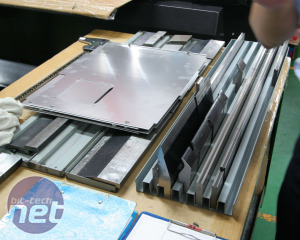

Bending into shape

Once all the cutting of the panels and components is complete, it's then time to bend the pieces: above is a range of tools used. They vary in length depending on how long the panel is that needs to be bent. We were told the bending tolerance is just 0.1mm and the staff are tested and trained monthly to check everything is tip-top.

There's about a dozen bending machines, with 3-4 spare for testing new methods and cases. In the year 3,000 they might be replaced by this.

Each part is measured and checked to make sure it's been shaped correctly to fit.

There was a box beside each machine with a few 'NG' parts in. One of them was picked out the box and despite its size within a few seconds our guide pointed out the failing: a minuscule bump in the very corner by a bend. It was the size of a pen-nib and he had to point it out with the nail on his little finger. Honestly, if my case came with that, I'd be hard pressed to have noticed let alone be bothered about it.

Not shown (sorry, my photos came out badly) is Lian Li's electronic soldering machine. We were told that affixing protruding threaded screw holes to a thin piece of aluminium is, at best, difficult. While most of Lian Li's case s are riveted together, in a few areas, such as fan mounts, screws are still required. Lian Li claims to be the only one in the industry using this method as it can either melt the metal or the fix doesn't hold, however the company claims to have found the right balance for a method of 'flash welding' a tiny bit of steel to its aluminium sheets.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.