Exploring CPU Cooler Design and Testing with Cooler Master

November 28, 2014 | 14:39

Companies: #cooler-master

Exploring CPU Cooler Design and Testing with Cooler Master

Though it is now well known for its cases, PSUs and peripherals, Cooler Master unsurprisingly began as a cooler and thermal solutions company over 20 years ago. Nowdays, it's one of the largest manufacturers in these segments globally, with a strong retail presence as well as a massive OEM channel, in which it produces stock coolers for CPUs, VGA coolers and motherboard heatsinks for many of the big names in various applications. It's one of the few companies with its own factory that can produce heat pipes, and it also manufactures its own closed-loop coolers; many on the market are made by CoolIT or Asetek. Evidently, cooling is a hugely important part of Cooler Master's business, and during our tour of its new HQ, we were fortunate enough to sit down with Ron Classen, product marketing specialist, to discuss the ways CPU coolers are designed and tested at the company.Designing a cooler begins by deciding on a type of cooler, and this can be affected by the main market being targeted. For example, Ron told us that German customers typically insist on coolers being as quiet as possible, while US customer are generally a lot less concerned (and Brits, being Brits, fall somewhere in the middle). High airflow coolers for overclocking and silent/ultra low noise coolers simply can't be the same thing, and the decision on cooler type will affect the entire design process.

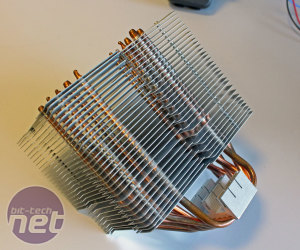

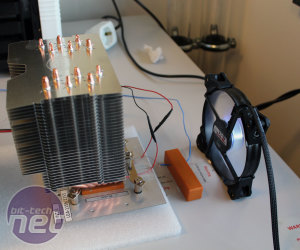

The vast majority of CPU coolers use the same basic principle of copper heat pipes and aluminium fins – copper absorbs heat very fast while aluminium gets rid of it more effectively. However, as the insane variety of coolers available shows, there's much more to it than this.

Consider heat pipes, for example. These work by sealing water in a copper tube in a vacuum so that the air pressure is very low. Correspondingly, the boiling point is lowered to around 30°C. As the heat pipe warms, the fluid quickly boils, and the resultant vapour passes through a powdered copper wick structure. This circulates the vapour through the heat pipe via capillary action and cools it down such that it becomes a liquid again and the cycle continues.

However, shape and size of heat pipes affect the Qmax value, the maximum heat transfer rate. Heat pipes are typically 6mm or 8mm thick in CPU coolers, and Ron told us that a single pipe can deal with approximately 45W and 55W of heat respectively, and this factors into the design choice of how many are used. Coolers designed for overclockers will typically use thicker and more heat pipes for this reason. The shape is also important – the more bending in a heat pipe, the less effective it is.

Then there's the aluminium fin design, for which you need to consider thickness, the distance between them and shape. Thicker thins require a greater distance between them to remain effective, and widely spaced fins are good at low airflow levels. Tightly packed fins (as well as water-cooling radiators) rely more on static pressure than airflow, so this ties into fan design too. As for shape, Ron described the middle of the cooler as a blind spot, due to the way fans work – often you'll see coolers indented behind the centre of the fan as using metal here is more or less useless.

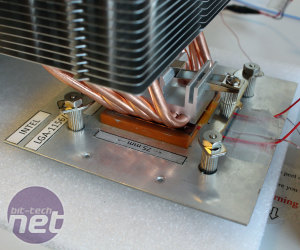

We also asked Ron to settle the debate once and for all on which was better – direct contact heat pipes or a copper baseplate. Ron's preference is continuous direct contact heat pipes, whereby the heat pipes directly touch the CPU as well as each other – as you can see in the cooler photographed, there's no spacing between them. This is because baseplates rely on solder to join them to the heat pipes, which is not an easy process to control at the manufacturing level since it's done manually, and the quality of the job can vary performance by as much as 5°C. It also uses more copper, which adds cost. Cooler Master's direct contact heat pipe technology has developed a lot over the years, but Ron admits that older coolers that use it may be worse than heatspreader counterparts.

Vapour chambers offer the best levels of heat absorption, which is why high end graphics cards often use them. It's a more expensive solution, but has been used in CPU coolers before, including Cooler Master's own V8 GTS and TPC 812.

We quizzed Ron on the importance of a cooler's mounting system too. He said they are typically designed more with usability in mind, and as long as they are able to exert a certain level of pressure (which engineers in the factory can measure), then it's fine. He also said that the LGA2011 socket requires a higher level of pressure to be effective than others.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.