Testing and Burning

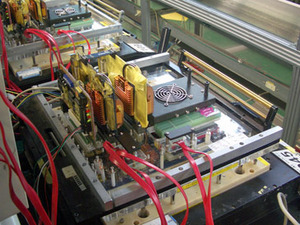

The boards get both a function and a burn-in test to check everything is working correctly. The test rigs aren't exactly pretty but they are functional enough to do the job. Finally there's also a visual inspection to make sure everything is a-OK before it gets packed up and stored...The storage boxes are labelled with which board is inside, and also what BIOS was flashed to the boards. This box of Gigabyte EP45-DS3R boards come shipped with the F4 BIOS, which is the initial release.

It was clear to see the scale of boards the factory churns out – just sitting on the floor were boxes upon boxes packed with all kinds of motherboards. On one side of one floor alone we counted ten boards per box, stacked four to five boxes high that went four rows deep to the wall at the back and this then went on for at least 50 rows as we walked down the floor. That's 10,000 motherboards sitting right there alone.

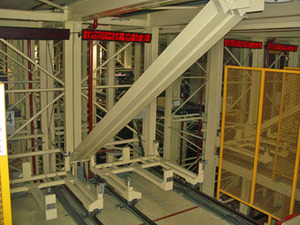

As we said before, the building was as tall as it is wide and long so the central storage system is a bit unlike other companies’ warehouses – it filled the space in a 3D map rather than a traditional floor plan. There were a couple of industrial lifts to ship stuff down to ship them out, as well as a few large internal arms that move pallets of products about for storage.

The reels (above right) are in storage and ready for use when needed. There was a small area where more reels were being prepared for use on the lines.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.