Sheffield-based LED specialist Lightcool claims to have developed a new dielectric material with three times higher thermal conductivity than copper, allowing for higher-power devices in smaller footprints.

Like any electronic device, an LED is not completely efficient: a percentage of the energy it takes in is wasted in excess heat, in addition to the light that you actually want. This heat must be dealt with, and just as with transistors on CPUs the smaller the LED gets the more difficult that becomes. Lightcool, an LED specialist based in Sheffield, claims to have developed a new dielectric material which promises to help with that problem by offering three times the thermal conductivity of copper.

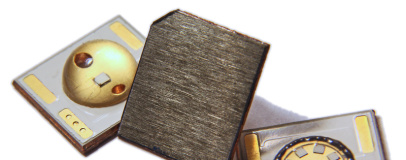

Traditionally, the dielectric layer of an LED is responsible for insulating the component electrically but also does so thermally - meaning that a large dielectric layer can cause an LED to overheat. Previous work had been carried out on reducing the footprint of the dielectric layer to solve this problem, but Litecool's new dielectric material - dubbed Black X - solves the issue by being more efficient at transferring heat than copper while still offering electrical insulation.

'It is an incredible material. We have always assumed dielectric materials will hinder the thermal performance of our LED packages but this material actually improves it,' crowed project engineer Robert Cobin of the new Black X dielectric. 'The thermal resistances of the LED packages we have made are so low we had trouble measuring it. We had to use 9 high power LEDs in one package to give enough power density to record any difference in temperature.'

James Reeves, chief executive of Lightcool, sees Black X - which the company claims offers a thermal conductivity of 1,000W/mK, three times that of copper and 30 times better than the alumina ceramic traditionally used as a dielectric in LED applications - as a major innovation. 'This is a step change in the performance of an LED package. We will be able to hit new lumen density thresholds without the need for costly heat sinks, heat pipes or fans,' he claimed at the company's announcement. 'We see this material initially being used in spot light applications for pin-point light sources but we also intend to incorporate it into our Lumen Block for the wider LED lighting market.'

Litecool has not yet indicated when the first Black X products will be on the market.

Like any electronic device, an LED is not completely efficient: a percentage of the energy it takes in is wasted in excess heat, in addition to the light that you actually want. This heat must be dealt with, and just as with transistors on CPUs the smaller the LED gets the more difficult that becomes. Lightcool, an LED specialist based in Sheffield, claims to have developed a new dielectric material which promises to help with that problem by offering three times the thermal conductivity of copper.

Traditionally, the dielectric layer of an LED is responsible for insulating the component electrically but also does so thermally - meaning that a large dielectric layer can cause an LED to overheat. Previous work had been carried out on reducing the footprint of the dielectric layer to solve this problem, but Litecool's new dielectric material - dubbed Black X - solves the issue by being more efficient at transferring heat than copper while still offering electrical insulation.

'It is an incredible material. We have always assumed dielectric materials will hinder the thermal performance of our LED packages but this material actually improves it,' crowed project engineer Robert Cobin of the new Black X dielectric. 'The thermal resistances of the LED packages we have made are so low we had trouble measuring it. We had to use 9 high power LEDs in one package to give enough power density to record any difference in temperature.'

James Reeves, chief executive of Lightcool, sees Black X - which the company claims offers a thermal conductivity of 1,000W/mK, three times that of copper and 30 times better than the alumina ceramic traditionally used as a dielectric in LED applications - as a major innovation. 'This is a step change in the performance of an LED package. We will be able to hit new lumen density thresholds without the need for costly heat sinks, heat pipes or fans,' he claimed at the company's announcement. 'We see this material initially being used in spot light applications for pin-point light sources but we also intend to incorporate it into our Lumen Block for the wider LED lighting market.'

Litecool has not yet indicated when the first Black X products will be on the market.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.