Front Cylinders - 2

The plan called for the cylinders to be joined with small strapping bands and PROTEX clips. With both the cylinders being fixed to a curved surface, and having to sit flush, despite straps and bands running behind them, I was in for some fun.

Starting with the two cut sections of pipe...

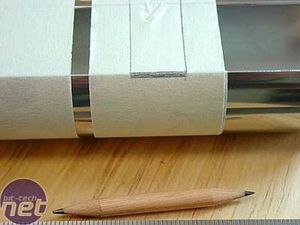

...I taped them both together, and marked where the bands were going to wrap around the back of the pipes. I shaded an area where the bands would cross the back edge...

...and set about grinding and filing and grinding and filing small notches in the back edges to allow the pipes to sit flush against the case. I initially tried using a Dremel with a grinding stone, but stainless steel was a bit much for it and I completely wore the stone away to nothing with barely a mark made! To work out the length of the bands, I wrapped some folded paper around the pipes...

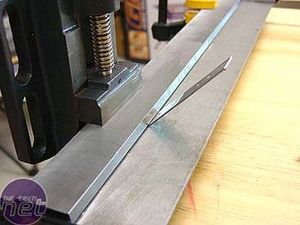

...and cut the steel bands I had to the right length. I bought the steel from a sheet metal wholesalers. It's 1mm stainless which I had them guillotine into strips the right width. All I would need to do later was cut it to length. After more measuring , I marked some fold

lines and drilled some screw holes...

...before clamping the strip into my sheet-metal folder and bending an angle into each side. I curved the back of the piece by hand, to match the curve of the case.

Once in place and recessed in the notches, each strip is secured by a couple of M4 socket screws, in threaded holes drilled near the back edges

of the pipes.

The catches on the PROTEX clips were flat - not an issue on the wide main cylinder, but they needed to be curved to fit the smaller pipe properly. I laid each one over the back of a bench vise and hammered it into a curve.

Each of the catches is fixed in place with 2 M4 socket screws that pass through both the band and the pipe section.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.