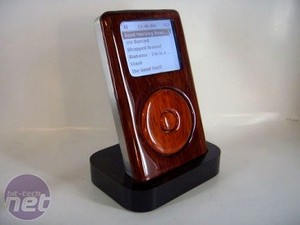

Foreword by Geoff Richards: The mercurial magician of modding, ZapWizard (aka Joshua Driggs), has created a modern masterpiece. Dubbed the Wood iPod, he'll talk you through its construction in his own words.

I have had a 20GB 4th gen iPod since they came out, but I have never liked the white finish. As part of Project Redwood, I am applying a wood finish to just about everything on my desk to have a matching set. The iPod was not excluded!

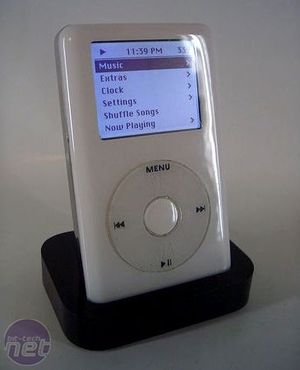

First off, this is the original iPod. (Note the white click wheel that was made to replace the gray wheel, it's already modded!). The dock was painted black, as it will sit inside a wooden cover.

First the iPod was taken apart. There are lots of guides on how to do this - this one has videos - but any website with instructions for iPod battery replacement will do fine. Once I had the shell separated I could start to work on the new faceplate.

I did not want to simply apply a wood veneer, or a fake finish to the iPod. I wanted to use real wood. To do this, I needed to carefully carve out a duplicate faceplate from a raw piece of wood. The wood I am using is African Padauk. It is a high quality hardwood that is very easy to work with, and naturally red in color.

This entire project was done by hand using a Dremel rotary tool. First the edges of the wood were curved (right) using a router attachment.

Next, the wheel was traced out in the proper place and cut out. After that, the hole for the screen was measured and cut out. I did this by first drilling holes to remove the bulk of the material.

The new fascia is an exact duplicate, or at least as exact as can be done by hand. By far the hardest part was carving out the back of the faceplate - the final thickness of the fascia was only 2mm thick. During this process the wood split four times, and was glued back using gorilla glue.

Next, a new screen has to be fabricated. This was done using a piece of lexan plastic, and was hand cut by dremel to fit the hole in the wood. It took two attempts to get a piece that fitted well.

In order to get the glossy finish that would approximate the finish on a normal iPod, I coated the wood with three coats of Envirotex Lite. The dust cover in this photo (annoyingly) touched the coating while it was setting and that area was sanded off before the final coat. A click wheel and select button were then cut out of African Padauk Veneer and given the same treatment. They are different in color as the veneer came from a different piece of wood.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.