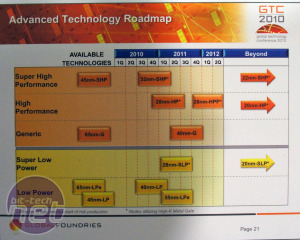

Global Foundaries, Global Technology Conference 2010

We recently attended Global Foundries, Global Technology Conference in Hsinchu, Taiwan to learn about some of the more techy things the company was now doing post-AMD split. Unlike when we see Intel, which applies its technology to real products you and I can buy, Global Foundries is exclusively a service for others now; including AMD as we know, ARM partners and even Microsoft's new 45nm Xbox 360 Slim 'CGPU' that's actually the world's first CPU and GPU in a single piece of silicon.What was particularly surprising was the achievements Global Foundries has managed in just 18 months of its spin-off from AMD. In that time it's bought and integrated Chartered Semiconductor, it's started building Fab 8 in Saratoga County, New York, it's expanding its Dresden Fabs and it's also upgrading its Singapore operations too. That's all in addition to asserting its own identity, rather living in the shadow of AMD.

If anything, the situation is reversed as AMD struggles (mostly financially) while Global Foundries seems to have built itself into an extremely strong competitor to the once dominant TSMC. The fact the conference was held in Hsinchu - TSMC's home turf - was clearly a shot across the bow to say 'we're here to tempt your home customers our way'. The irony being that some of TSMC's biggest customers are not Taiwanese though, being AMD's graphics division and Nvidia.

What was notable is that Global Foundries rarely, if ever, compared itself to Intel throughout the entire event. It considers its competitors other foundries and quietly ignores the fact that Intel is the process leader in a lot of competing technologies. However, in some respects we can understand why though: Intel only ever manufacturers for itself, whereas Global Foundries serves the entire semi-conductor market. With this in mind it's easier to understand why certain fabrication decisions are made by both parties.

The state of the union

With a $3.6 billion revenue and $2.5 billion per year investment, Global Foundries means serious business.Currently its Singapore Fab 7 operations are handling everything from 130nm to 65nm manufacturing as well as all the older 200mm wafers, but it will move to take over the 45/40nm reigns as the currently expanding Dresden Fab 1 facilities move to 32/28nm nodes below this. Singapore and post-expansion Dresden will output 130,000 wafers a month between them, and when New York Fab 8 comes online next year Global Foundries total production capacity will increase to 190,000, 300mm wafers per month. Massive capacity is a bonus, but it's not everything though.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.