Fujitsu Laboratories has released details of a new heatpipe design built for slim electronics, boasting a sub-millimetre thickness and five times greater heat transfer than existing solutions.

Designed with smartphones and tablets in mind, the loop heatpipe works in much the same way as any other: an evaporator panel absorbs heat from the target electronics, which evaporates a liquid coolant contained within the loop; this coolant passes through the loop to a condenser, typically located in a cooler portion of the device and with a larger surface area, which sheds the heat and turns the coolant vapour back into a liquid for return to the evaporator portion.

Heatpipes are a common sight in modern electronics, but they're rather too bulky for use in ultra-slim smartphones and tablets. Fujitsu's new model aims to solve that: using six 0.1mm-thick copper sheets, two surface sheets and four inner-layer sheets, the new loop heat pipe design reduces the 10mm thickness of an average evaporator to just 0.6mm and the condenser to just shy of 1mm. The result: a fully-functional heatpipe suitable for even the slimmest of devices.

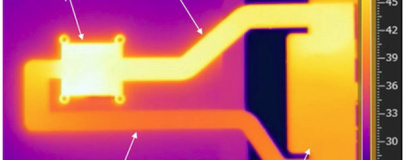

According to Fujitsu's test results, carried out on a working prototype of the heatpipe, the new design is not only thin but considerably more efficient: its heat transfer capabilities are claimed to be five times higher than previous thin heatpipes or thermally-conductive sheeting solutions.

Fujitsu's creation is to be formally unveiled at the Semiconductor Thermal Measurement, Modelling and Management Symposium (SEMI-THERM) in California later this week. The company has stated it is 'examining potential applications' outside the mobile realm, and plans to have the first practical implementation by 2017.

More information on the design is available on Fujitsu's official website.

Designed with smartphones and tablets in mind, the loop heatpipe works in much the same way as any other: an evaporator panel absorbs heat from the target electronics, which evaporates a liquid coolant contained within the loop; this coolant passes through the loop to a condenser, typically located in a cooler portion of the device and with a larger surface area, which sheds the heat and turns the coolant vapour back into a liquid for return to the evaporator portion.

Heatpipes are a common sight in modern electronics, but they're rather too bulky for use in ultra-slim smartphones and tablets. Fujitsu's new model aims to solve that: using six 0.1mm-thick copper sheets, two surface sheets and four inner-layer sheets, the new loop heat pipe design reduces the 10mm thickness of an average evaporator to just 0.6mm and the condenser to just shy of 1mm. The result: a fully-functional heatpipe suitable for even the slimmest of devices.

According to Fujitsu's test results, carried out on a working prototype of the heatpipe, the new design is not only thin but considerably more efficient: its heat transfer capabilities are claimed to be five times higher than previous thin heatpipes or thermally-conductive sheeting solutions.

Fujitsu's creation is to be formally unveiled at the Semiconductor Thermal Measurement, Modelling and Management Symposium (SEMI-THERM) in California later this week. The company has stated it is 'examining potential applications' outside the mobile realm, and plans to have the first practical implementation by 2017.

More information on the design is available on Fujitsu's official website.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.